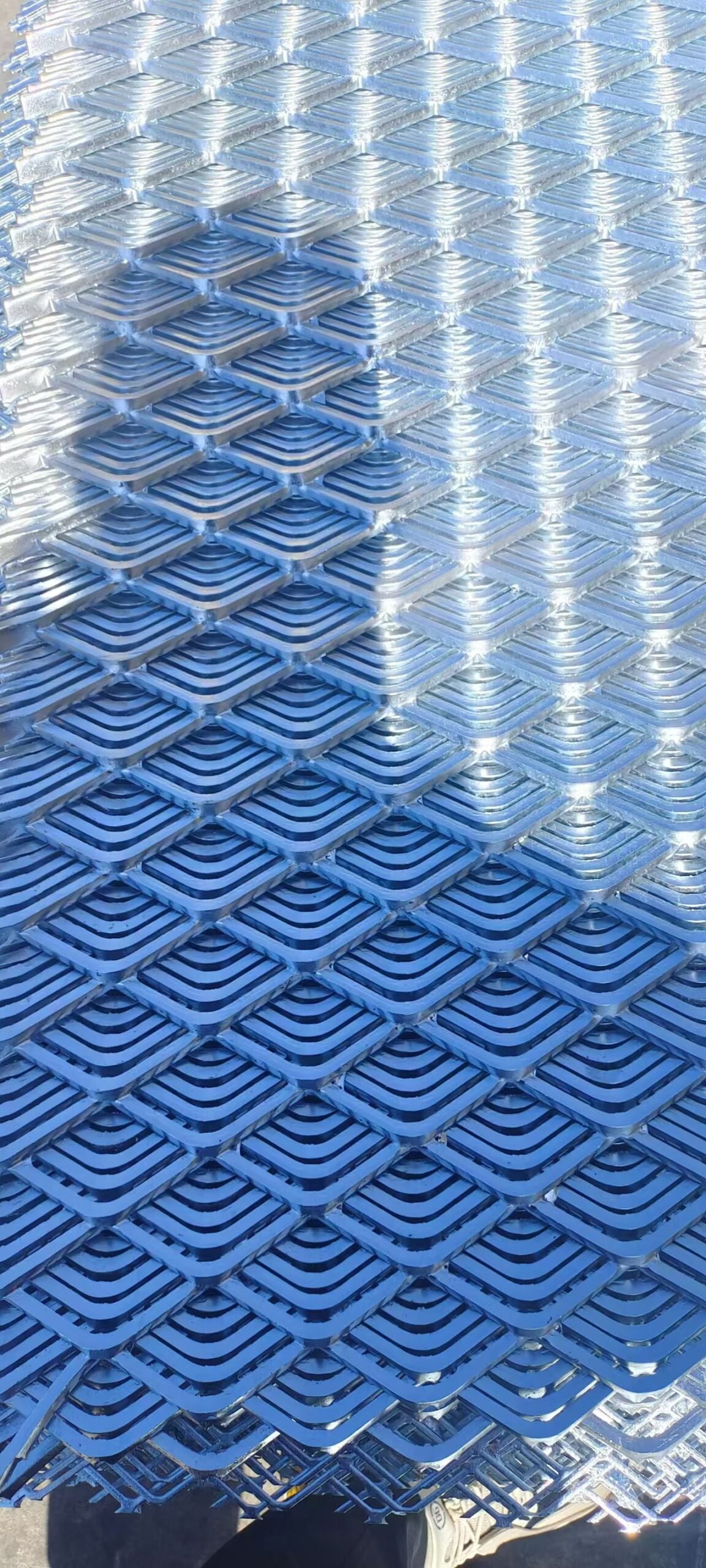

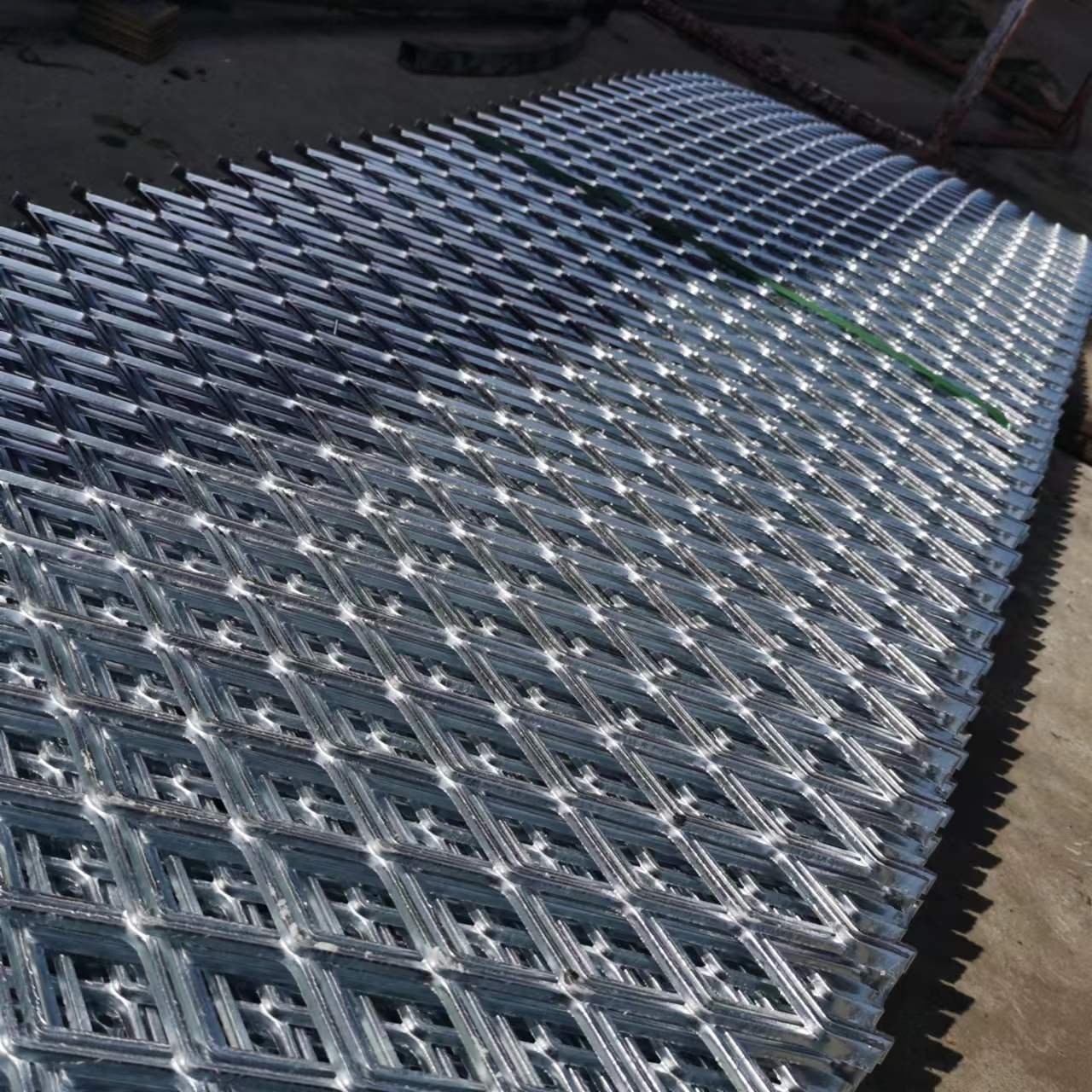

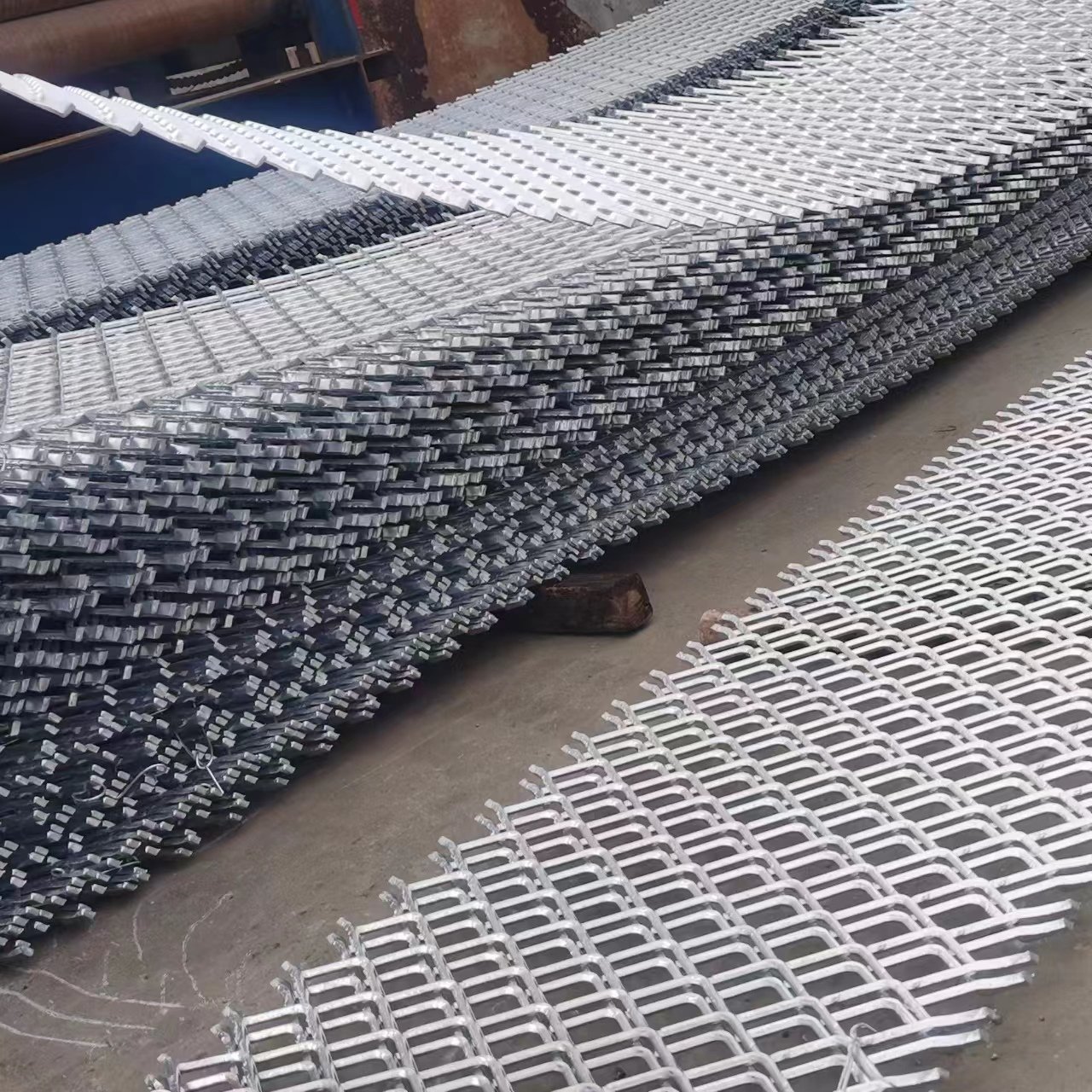

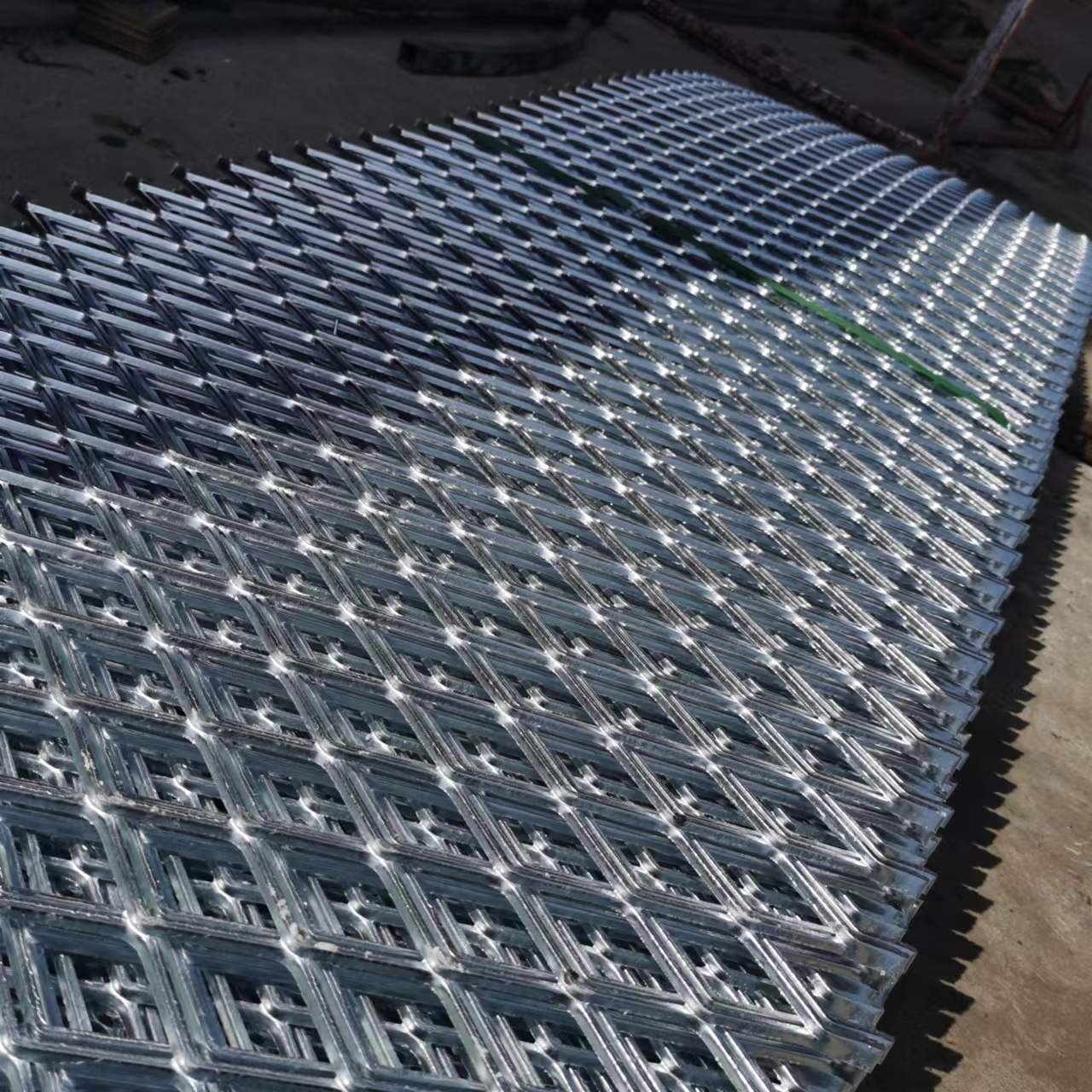

Galvanized steel mesh

Hot-Dip Galvanizing

Hot-Dip Galvanising | Durable, Bonded Zinc Coating for Steel.

Hot-dip galvanising is a superior metallurgical process that creates a permanent, corrosion-resistant barrier by immersing prepared steel into molten zinc. This forms a robust alloy layer that is integrally bonded to the steel substrate, offering unmatched protection.

Our Step-by-Step Galvanising Process:

Pickling: The steel component is thoroughly cleaned in an acid bath to remove all surface contaminants, rust, and iron oxide (mill scale), providing a pristine surface for the reaction.

Fluxing: The item is then rinsed and immersed in a fluxing agent (often an ammonium chloride or zinc chloride solution). This critical step prevents oxidation of the clean steel surface prior to dipping, ensuring optimal zinc adhesion.

Galvanising (Zinc Immersion): The prepared steel is dipped into a kettle of molten zinc. A metallurgical reaction between the iron and the zinc occurs, forming a series of tough zinc-iron alloy layers.

Why Choose Hot-Dip Galvanised Protection?

Superior Adhesion: The coating is not merely a paint-like layer; it is a metallurgically bonded part of the steel, making it virtually impossible to peel or flake off, even when scratched or bent.

Complete & Uniform Coverage: The immersion process ensures that all surfaces, including edges, corners, and hard-to-reach areas, are equally protected.

Longest Service Life: This process delivers the most effective and durable anti-corrosion performance available, significantly extending the product’s lifespan and reducing total cost of ownership by eliminating the need for frequent maintenance or repainting.

Sacrificial Protection: Even if the coating is damaged, the surrounding zinc will sacrificially corrode to protect the underlying steel, preventing rust from spreading.

Invest in long-term durability. Specify hot-dip galvanised steel for your most demanding projects.